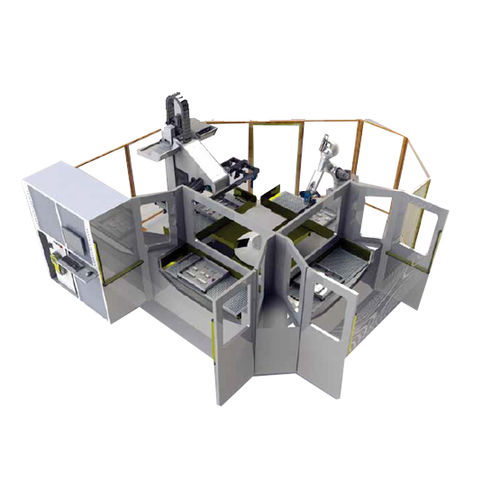

Pick and Place Robotic Cell

A pick and place robotic cell is an automated system that utilizes robotic technology to efficiently handle, pick up, move, and place objects in predefined locations. This cell consists of robotic arms, grippers, sensors, and a control system, all integrated to work seamlessly together. The primary purpose of a pick and place robotic cell is to automate repetitive tasks that involve transferring objects from one location to another, such as assembling components on a production line, placing products into packaging, or sorting items based on specific criteria.

Pick and place robotic cells offer numerous advantages, including increased production speed, reduced labor costs, enhanced accuracy, and improved safety by minimizing the need for human intervention in repetitive tasks. These cells are widely used in industries such as manufacturing, electronics, logistics, and food processing, where precision and efficiency are essential. The integration of robotics and automation in pick and place cells exemplifies how technology can elevate productivity, streamline operations, and optimize workflows, all while ensuring consistent and reliable handling of objects.